MONITORING & REPORTING

Our treatment programs include daily and long-term monitoring that can be designated as process and performance monitoring.

PROCESS MONITORING

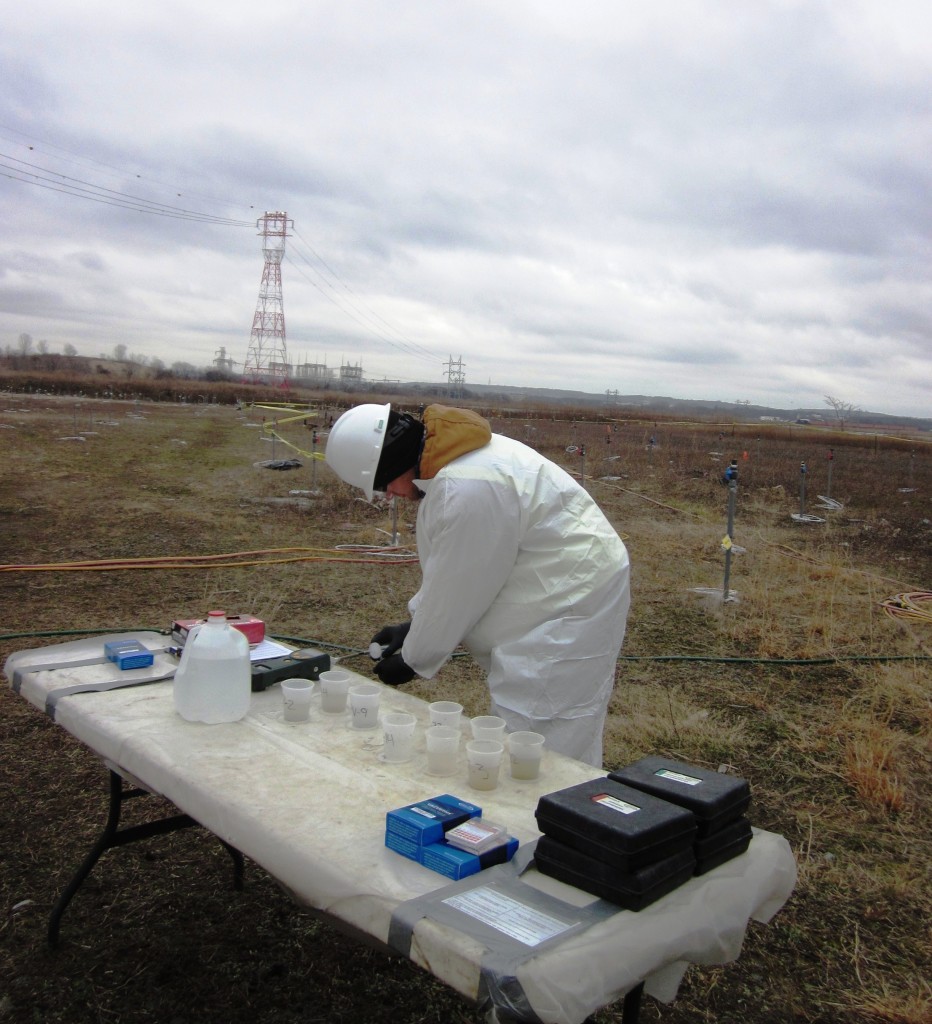

Field process monitoring will vary depending upon site-specific conditions, remediation design and reagents utilized. Process monitoring refers to analyses of groundwater and off-gas samples collected within and adjacent to the treatment area, during implementation of the in-situ chemical treatment program, and also systems monitoring to ensure a safe and effective process. The purpose of the process monitoring is to determine if appropriate geochemical conditions are established in the aquifer, reagents are distributed effectively, and an efficient oxidation reaction is  occurring. For example, during catalyzed hydrogen peroxide injection programs groundwater samples are collected from monitoring and injection wells within and adjacent to the treatment area. Groundwater samples are collected daily, prior to beginning the injection each day. Some of the parameters to be measured are groundwater pH, dissolved iron, hydrogen peroxide concentration, and temperature. These parameters cumulatively reflect the distribution of the oxidant and monitors geochemical conditions to ensure they are appropriate. Other parameters may be evaluated if activated sodium persulfate, permanganate or zero valent iron are the reagents being applied.

occurring. For example, during catalyzed hydrogen peroxide injection programs groundwater samples are collected from monitoring and injection wells within and adjacent to the treatment area. Groundwater samples are collected daily, prior to beginning the injection each day. Some of the parameters to be measured are groundwater pH, dissolved iron, hydrogen peroxide concentration, and temperature. These parameters cumulatively reflect the distribution of the oxidant and monitors geochemical conditions to ensure they are appropriate. Other parameters may be evaluated if activated sodium persulfate, permanganate or zero valent iron are the reagents being applied.

Process monitoring is an ongoing process, and results are utilized to continuously optimize the ongoing injection process. Geo-Cleanse typically performs all process monitoring during the treatment program.

PERFORMANCE MONITORING

Performance monitoring refers to the collection and analysis of soil and groundwater samples to evaluate pre-treatment and post-treatment contaminant concentrations. Sample analysis is typically limited to the contaminants of concern, however additional analytes of interest may be included. The type, quantity and frequency of sample collection will be site-specific and can vary between sites. We frequently conduct pre-treatment performance monitoring during injection well installation to minimize costs and confirm contaminant distribution and mass. Performance monitoring is typically conducted by our client’s representative.

REPORTING

Throughout the duration of the injection, Geo-Cleanse provides weekly updates to our clients containing injection quantities and field observations. Following the completion of the injection, Geo-Cleanse provides a progress report complete with the data collected during the injection. Once post-treatment analytical results are received, Geo-Cleanse issues an effectiveness evaluation report, which details the installation of the injectors, complete with boring and construction logs, an analysis of the baseline contaminant mass, a summary of the field activities and observations, and an analysis of the effectiveness of chemical oxidation on the contaminant mass.

Throughout the duration of the injection, Geo-Cleanse provides weekly updates to our clients containing injection quantities and field observations. Following the completion of the injection, Geo-Cleanse provides a progress report complete with the data collected during the injection. Once post-treatment analytical results are received, Geo-Cleanse issues an effectiveness evaluation report, which details the installation of the injectors, complete with boring and construction logs, an analysis of the baseline contaminant mass, a summary of the field activities and observations, and an analysis of the effectiveness of chemical oxidation on the contaminant mass.